La Guía Definitiva: 4 Pasos de Cómo Personalizar Botones para Jeans Personalizados Para Su Marca

Los jeans no son nada sin los accesorios de metal. No es fácil crear una marca, pero hacerlo todo con el nombre personalizado es más difícil. Así que hoy vamos a mostrar todos los detalles de cómo usar botones para jeans personalizados y remaches jeans para una marca jean, una demostración paso a paso. Empecemos por aquí.

Paso 1 Comunicación total entre la marca y el fabricante

La comunicación es esencial al principio. Debe aclarar con el fabricante qué tipo de botones para jeans personalizados y remaches metálicos necesita o los adornos metálicos. ¿Cuáles serán los colores adecuados para combinar con su tela jean?

Si va a lavar los adornos metálicos junto con los jeans o no, si necesita normas libres de productos químicos o tiene que pasar la prueba de las agujas de las máquinas. ¿Cuál es su presupuesto, etc.? Después de fijar todos estos detalles, podrá obtener los diseños y colores más satisfactorios.

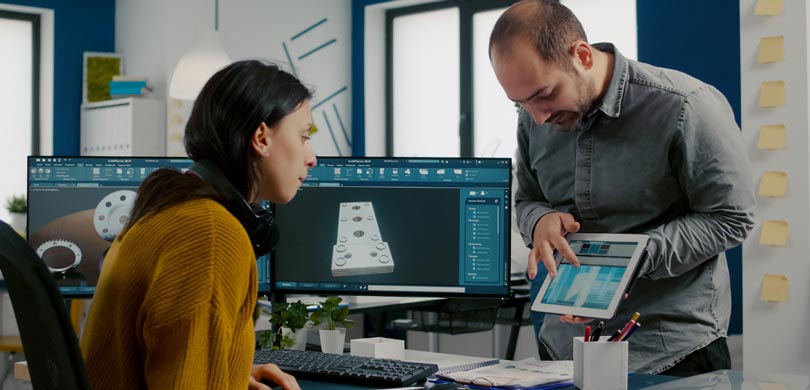

Paso 2. Realización de diseños en 3D y aprobación del material gráfico

Después de fijar los detalles de los requisitos, el diseño del artwork se convierte en el paso esencial. Normalmente, los técnicos de la fábrica utilizan programas informáticos para dibujar las ilustraciones en 3D de los botones y remaches con el nombre de la marca.

Lo mismo ocurrirá cuando salgan las muestras físicas. Lo que quiero decir es que este es un paso esencial porque tiene que comprobar cuidadosamente cada detalle del artwork, el tamaño, la forma, la ortografía del logotipo, etc.

Si se le escapa algún pequeño error, el otro proceso seguirá adelante con el mismo error, y una vez que encuentre el error en las muestras, ya será demasiado tarde.Y si quiere revisarlo de nuevo, tendrá que volver al paso 2 y confirmarlo todo antes de rehacer todas estas muestras. Así que tenga paciencia y preste más atención a este paso.

Paso 3 Procesar las muestras

Ahora es el paso de aprobar las muestras. Mucha gente piensa que es fácil hacer las muestras ya que se trata sólo de unas pocas piezas cuando reciben las muestras finales. Pero en realidad, hacer las muestras es lo mismo que hacer la producción, no hay nada diferente. He aquí cómo salen los botones metálicos y los remaches (igual que el muestreo y la producción a granel)

- Cuando se aprueben las ilustraciones y los diseños en 3D, el personal técnico moldeará las máquinas CNC para curvar el diseño según sea necesario.

- A continuación, las máquinas de estampado estamparán la tapa en bruto de los botones de latón, y las máquinas de fundición a presión por inyección harán el bruto de los botones de zamak.

- Se pulirán las tapas en bruto de los botones y remaches de zamak para que la superficie quede lisa, en el caso de los botones de latón, se lavarán las tapas en bruto para que queden limpias, todo esto se hace para obtener los buenos colores durante la galvanoplastia de color.

- Las tapas en bruto de los botones y remaches se someterán a la galvanoplastia de color. Después de pulirlas y limpiarlas bien, las tapas se someterán al proceso de galvanoplastia.

- Ensamble las tapas con la parte inferior después de que los colores estén listos para el chapado. Este paso puede hacerse manualmente o con máquinas automáticas.

- Probar la fijación de los botones y remaches en la tela para ver si funcionan bien, y hacer la prueba de tracción para saber si es lo suficientemente fuerte.

- Enviar a los clientes para su aprobación.

Algunos clientes se quejan de que el coste de las muestras es cada vez mayor. Cuando sepa cómo salen las muestras, comprenderá que el precio no es sólo por los botones en sí, sino también por el tiempo, la energía y mucha atención.

Paso 4 Producción a granel y entrega

Una vez aprobadas las muestras, llegamos al último paso. La mayoría de las veces, la producción a granel es estable y sin problemas, ya que siguiendo las muestras no habrá ningún problema.

Pero hay una cuestión a la que debemos prestar atención, que son los colores de producción. La galvanoplastia es un proceso semiautomático. Sigue necesitando que los técnicos hagan algunos ajustes. Así que la cuestión es que los colores en la producción serán ligeramente diferentes de los colores de las muestras. En este caso, puede considerarlo como cocinar.

El mismo cocinero no puede hacer el mismo sabor cada vez, igual que en la galvanoplastia. Los técnicos no pueden igualar el color exacto al 100% en cada operación. Además, la ligera diferencia no afectará al resultado final después de fijarlo a los jeans.

Este es todo el proceso de los adornos metálicos personalizados, y es bastante fácil de controlar tras unas cuantas operaciones. Así que, después de todos estos bonitos jeans metálicos, botones y remaches con su marca, ahora es el momento de impulsar la marca y obtener grandes beneficios.

ARTÍCULOS RELACIONADOS